Seymour have been heavily involved with Planers from the start of the company. This is through maintaining machines, repairing, retrofitting and re-engineering machines. Keeping planers productive can be an issue as the electrics and mechanics ageing. This lead to our solution and the start of the development of the E-NC Strategy. The E-NC is in continuous development and has evolved over the years from Trio motion control to the current Siemens system.&ndp; The systems have been fitted to Butler, Stirk and Planers of Huddersfield Planers and can be fitted to any planer.

The current Electrical and software package is extremely flexible and ties in with both our E-Grind and E-Mill programs allowing for improved and increased functionality from your planer. The use of servo control eliminates many of the common causes of mechanical and Hydraulic failure seen in Planer machines and provides the ability to add more automation and better performance of your machines.

Although the start of the program was for the Rail industry over the years this has diversified with features and improvements useful in many industries including general manufacturing and paper machine manufacture.

This was the first E-NC project.

Butler Planer with new control pendant |

This Butler planer has given decades of service planing rail for the manufacture of point and crossings. The mechanical feed box for the planing slides was approaching the end of it's useful life. The Electro-magnetics panel components were continually failing due to age, the price of replacing failing items was escalating and the presence of asbestos was causing serious health and safety issues.

The solution to these problems was to remove the Electro-magnetics panel, remove the motor-generator set, remove the mechanical feed drive box and replace with new technology including DC drive, servo motor and drive, programmable simple NC control. The removal of this equipment also had the benefit of reducing the floor space required for the machine. While this work was being carried out the opportunity was taken to refurbish the cross rail slides

The project included;

- Simple NC control of the tool slides.

- Programmable feed increments.

- Total cut depth with automatic stopping of the machine at the desired depth.

- Control of the machine from a single operator pendant.

- Generally improvement of the reliability of the machine.

- Reduced wear and smoother running of the table drive mechanics.

- Machine fault monitoring and messaging.

- Safe modern electrical control with simple maintenance.

- Production times have been reduced due to easier and quicker operation.

- Maintenance costs and downtime have been dramatically reduced.

- The machine operators prefer this to the original machine.

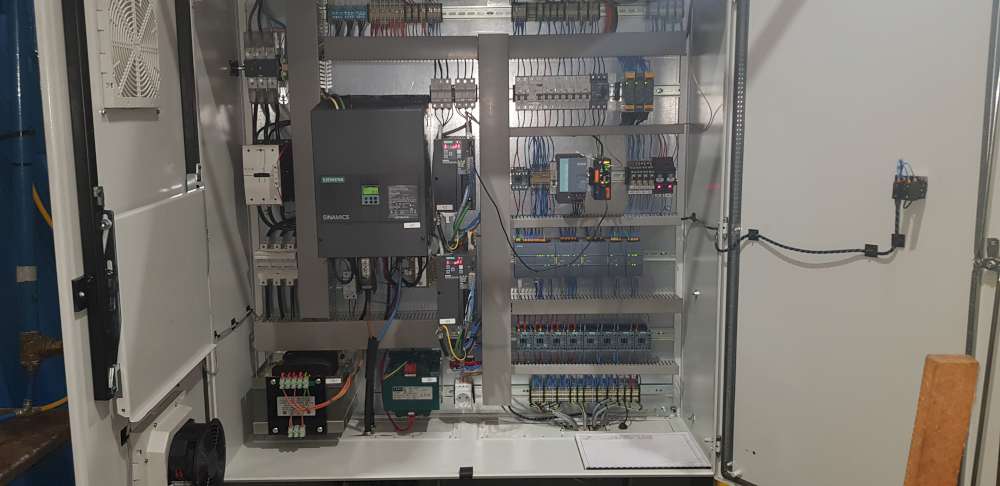

Main Electrical Panel |

Planers of Huddersfield Planer

The Latest E-NC project.

New control pendant with touch screen |  Seymour Re-Engineered Planer with Compliant guarding | |

New Main Electrical Panel |

This machine had an electrical failure and the with the table drive system. Over the years over parts of the machine had failed including the hydraulic feed for the tool slides. The New Electrical package and mechanical re pairs and re-engineering brought all the functions of the machine back into service and added a lo more functionality.

The project included;

- All the Benefits of the original Seymour E-NC plus

- New Table drive coupling design and gearbox repair

- Dual tool slide servo control, one for the rail mounted boxes and one for the Slide box

- program move a set distance

- position display

- Input of feed rate directly as well a using dials

- Remote secure Diagnostics - Seymour base over the internet

- Input setting and set-ups over the factory network

- Machine monitoring over the factory network

- Fully compliant interlocked and integrated guarding

|

|

Email:- info@seymour-eng.com |

|

Siddal Hall Works, Phoebe Lane, Halifax, ENGLAND, HX3 9AS |  |

| TEL:- +44 (0) 1422 362 135 | FAX:- +44 (0) 1422 322 511 |

BUTLER PLANER

BUTLER PLANER