The SEYMOUR F-Type is designed and manufactured in Halifax, England.

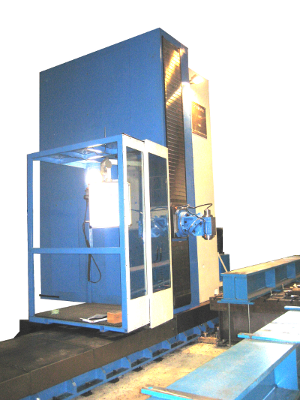

The big advantage of a floor type machine is that the factory can be the work table for the machine allowing very large fabrications and castings to be presented to the machine for precision metal removal.

The F-Type is suited to both Large and small jobs, it is a truly universal milling and boring machine.

The spindle speeds and power curves will be specified to match the tooling requirements.

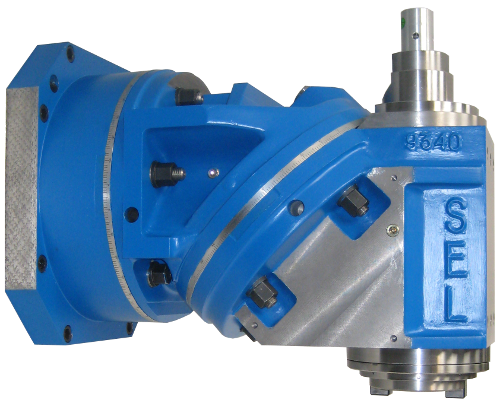

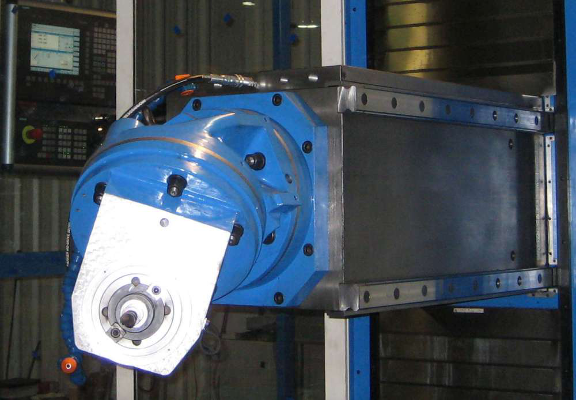

A range of milling heads of both manual and automatic types are available.

Good Foundations save you money

Conventionally floor type milling and boring machines have to be installed in a pit, the F-Type is designed to have a lower minimum spindle height than conventional machines and therefore can be installed at floor level. This potentially reduces the cost of foundation work when compared to pit installed alternative machines. The machine can also be manufactured to fit on an existing foundation, completely eliminating the requirement for a new foundation.

F-Type versions are available configured specific sectors including;

- General purpose universal milling machine.

- Fabrication and construction.

- Hard material milling machine for the likes of rail and hard steel alloys such as inconel.

- High speed machining for aluminium and aerospace type work.

The F-Type is designed in a modular manner to allow different options to be easily specified. The basic machine is aimed at customers who just want to cut metal and need nothing more than a well designed, robust, CNC controlled, easy to use milling & boring machine. Customers can request any option that might be required, be they purely technological or relating to the machine structure and modules used. A typical list options would be;

- Part probe

- Tool measuring probe

- Rotary tables

- Dividing Heads

- Box tables

- Floor plates

- Angle plates

- Tool changer

- Spindle power

- Right angle head

- Automatic universal head (1/1 degree or 3/3 degree)

- Axis rapid rate

- Axis travels

- CNC system (Siemens, Heidenhain or Fagor, others available on request)

- High pressure coolant

- Air chip removal / coolant system

- Swarf conveyor

- Perimeter guarding systems

- Bespoke CADCAM system

- .............And any other requirements

The F-Type can be supplied to various specifications and it is possible to make the machine fit your exact requirements, typical specifications would be;

| Feature | Values | |

| Machine Travels | ||

| Length (m) | From 2 up to any required (photos show 13m) | |

| Width - Ram (mm) | 550, 750, 1050, 1250, 1500 | |

| Height (mm) | 500, 1000, 1500, 2000, 2500, 3000, 3500, 4000 | |

| Spindle | ||

| Power S6(kW) | 24 to 56 | |

| Power S1(kW) | 16 to 37, (22kw typical) | |

| Spindle Speed (RPM) | 1500, 2000, 2500, 3000 | |

| Spindle Taper | 50 int. (DIN69871 /A) | |

| Feeds | ||

| Feed (mm/min) | 2500, 5000, 7500, 10000 | |

| Rapids (mm/min) | 10000, 15000, 20000 | |

| CNC Control | Siemens 840D SL (Standard) | |

| Siemens 828D SL | ||

| Heidenhain TNC | ||

| Fagor | ||

| Fanuc | ||

| Others on request |

These are by no means the definitive specifications, please call or email to discuss your exact requirements or for SEYMOUR to recommend a specification to meet your needs.

For further information contact Seymour Engineering by email, post or through our form.

The use of the very latest technology allows the machine to not only meet current safety standards but to also reduce the energy requirements and the environmental impact of the machine.

The design philosophy was to reduce the number of components, allow maximum access for maintenance, maximize efficiency and allow the maximum flexibility of the specification.

The F-Type has been designed so the machine can be manufactured to suit customer requirements, shorter or taller columns, longer or shorter rams can be cast and the X axis travel can be shortened or extended to practically any conceivable length.

The F-Type is part of the Seymour  Range of machines. These machines are designed with efficiency in mind making the F-Type a good investment for your companies future.

Range of machines. These machines are designed with efficiency in mind making the F-Type a good investment for your companies future.

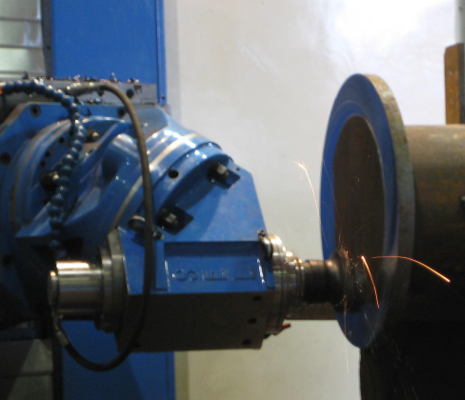

The combination of the universal head and the inbuilt cycles in the CNC make machining on any plane simple and convenient.

|

|

|

||

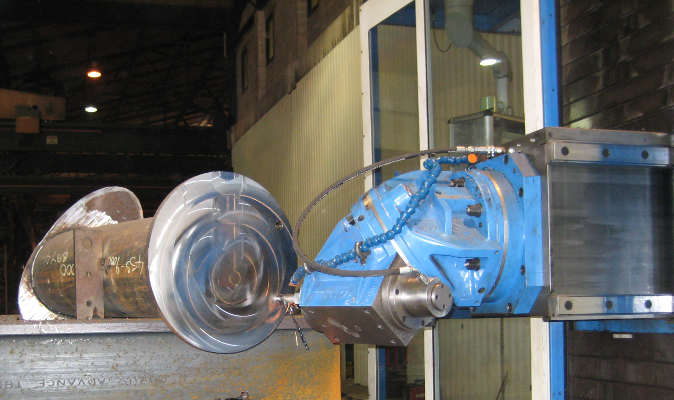

| Drilling on a rotated plane. Arcelormittal Orbit bearing face |

Interpolated milling on a rotated Plane. Arcelormittal Orbit bearing face |

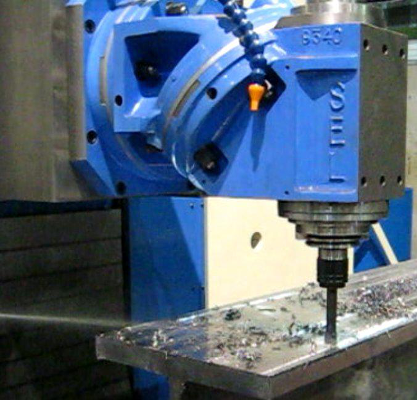

Drilling |

|

|

|

||

| Face milling | Tapping | Probing using 3D radio work piece probe |

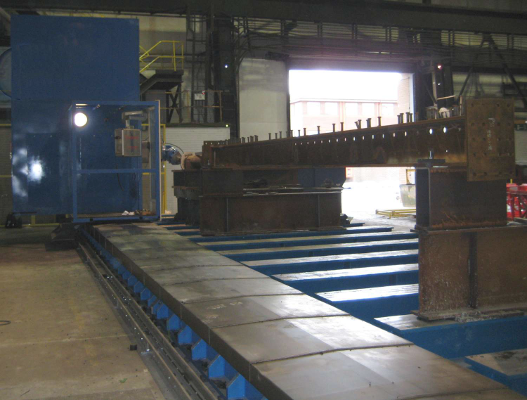

The versatility of a floor type machine allows for many different work holding options to be employed.

|

|

|

| F-Type set up for machining large Fabs on floor mounted steel buffets. Machine shown: 13m X travel and 3m vertical travel. |

F-Type Machining Fabs for conventional T-Slotted tables. Machine shown: 13m X travel and 1.5m vertical travel. |

Feel free to contact  with any questions.

with any questions.

|

|

Email:- info@seymour-eng.com |

|

Siddal Hall Works, Phoebe Lane, Halifax, ENGLAND, HX3 9AS |  |

| TEL:- +44 (0) 1422 362 135 | FAX:- +44 (0) 1422 322 511 |

Universal Floor type milling and boring machine

Universal Floor type milling and boring machine