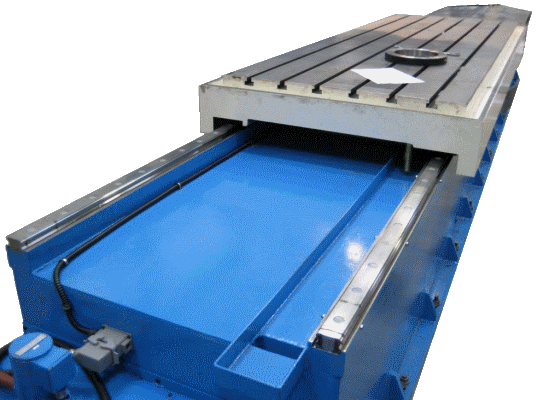

The SEYMOUR T-Type is designed and manufactured in Halifax, England. The T-Type is a truly universal milling and boring machine. The machine is suited to small to medium sized jobs up to 20 tonnes. The large table affords the versatility to work on one larger component or multiple smaller ones. There are two main advantages of a moving table machine, firstly the machine is self contained within it's own foot print and secondly the moving of the job allows for easier loading especially when craneage or lifting is restricted. It is also possible for longer components to overhang the ended of the table with the full size base being more stable than other moving table designs as the table itself never overhangs.

The T-Type has been designed to be an extremely versatile machine to meet users requirements as efficiently as possible. The Specification versatility of the machine itself is proved by nature of the fact that the machine is made up of the B-Type Column, head slide and ram assembly and the table is from the SEL-xT product. Further versatility is afforded due to the design and manufacture process common with the E-Mill philosophy, the machine can easily be tailored to suit your requirements such as factory space, job or process.

The T-Type is designed for efficiently, in common with the B-Type, the standardization on the Siemens 828Dsl coupled with the latest highly efficient Sinamics motors and combi drive allows for a very compact design and high optimization of the servo and CNC equipment. The Siemens 828Dsl runs Siemens Operate with Shopmill meaning that the end user programming and operation of the machine is identical to the 840D. The 828Dsl is the obvious choice for worldwide support allowing quick service and spares delivery if required in the future.

The T-Type is a very versatile machine designed to be at home in many sectors. This moving table type machine is the de facto standard for small milling machines. The Seymour T-Type is designed to fit between the small machining centres and the larger moving column machines allowing for benefits of both types to be enjoyed by the user, the large weight and/or high volume batches in a single set as with the moving column machines with the closed foot print and ease of loading of a small machining centre. Coupled with the versatility of a HD30 milling head, or other interchangeable heads to suit the jobs in hand. The T-Type is equally at home machining;

- General purpose jobbing shop work.

- High through put batch work.

- Fabrication and construction.

- Hard material milling machine for the likes of rail and hard steel alloys such as inconel.

The T-Type is designed in a modular manner, allowing customer driven specification versatility at the outset when ordering a machine. The basic machine is a well designed, robust, CNC controlled machine that is easy to use for both milling & boring and it is an excellent platform for Customers to add options as required, be they purely technological or relating to the machine structure and modules used. A typical list options would be;

- Part probe

- Tool measuring probe

- Rotary tables

- Dividing Heads

- Angle plates

- Tool changer

- Spindle power

- Right angle head

- Automatic universal head (1/1 degree or 3/3 degree)

- Axis travels

- Different CNC system

- Bespoke coolant systems

- Perimeter guarding systems

- Bespoke CADCAM system

- Custom Fixtures

- ........And any other requirements

The T-Type is part of the Seymour  range of machines. These machines are designed with efficiency in mind making the T-Type a good investment for your companies future.

range of machines. These machines are designed with efficiency in mind making the T-Type a good investment for your companies future.

At SEYMOUR we believe in keeping design and technical expertise in house, this gives us the greatest flexibility allowing bespoke design issues to be incorporated into the machines. Examples of this are the ability to provide a special purpose head or adding specific technologies.

The use of the very latest technology allows the machine to not only meet current safety standards but to also reduce the energy requirements and the environmental impact of the machine.

The design philosophy was to reduce the number of components, allow maximum access for maintenance, maximize efficiency and allow the maximum flexibility of the specification.

The B-Type and T-Type share a common platform utilizing the same components and design pathways. This emphasizes the E-Mill philosophy of efficiency of design, specification, verification and validation

The T-Type can be supplied to various specifications, and it is possible to make the machine fit your exact requirements, typical specifications would be;

| Feature | Values | |

| Table | - excluding coolant returns | |

| Length (mm) | 3000 to 5000 | |

| Width (mm) | 1000 | |

| Nominal Height (mm) | 800 | |

| Component Mass(Kg) | Up to 10,000 or 20,000 | |

| Machine Travels | ||

| Length (mm) | 3115 to 5115 (table +115) | |

| Width - Ram (mm) | 1000 | |

| Height (mm) | 1000, 1575 | |

| Spindle | ||

| Power S6(kW) | 22.8 | |

| Power S1(kW) | 12 | |

| Torque Peak (Nm) | 750 | |

| Torque S1 (Nm) | 375 | |

| Speed (RPM) | 2000, 2500 | |

| Taper | 50 int. (DIN69871 /A) | |

| Feeds | ||

| Feed (mm/min) | 2500, 5000, 7500, 10000 | |

| Rapids (mm/min) | 10000 | |

| CNC Control | Siemens 828D SL, Others on request | |

| Coolant Systems | M08 Liquid (Standard) | |

| M07 Air (Standard) |

These are by no means the definitive specifications, dimensions, feeds, speeds, powers and travels can be produced as required. please call or email to discuss your exact requirements or for SEYMOUR to recommend a specification to meet your needs.

For further information contact Seymour Engineering by email, post or through our form

. |

|

|

| HD30 universal head. Other heads available. |

Operator pendant with articulated arm to allow positioning inside and outside of the operator cabin |

|

|

| Ram extended over the bed | Radio Probe |

Machining on rotated planes made easy

The Siemens inbuilt support for the universal head make machining on angled planes very easy. We configure the machine to do the hard work for you. Tell the machine the angle to machine at and it calculates the angles for the head joints and sets the working plane, no need for look up tables or trig. The operator can then easily programme the machine in the working plane and jog the machine relative to either the working plane or the default machine plane.

Feel free to contact  with any questions.

with any questions.

|

|

Email:- info@seymour-eng.com |

|

Siddal Hall Works, Phoebe Lane, Halifax, ENGLAND, HX3 9AS |  |

| TEL:- +44 (0) 1422 362 135 | FAX:- +44 (0) 1422 322 511 |

Universal Table type milling and boring machine

Universal Table type milling and boring machine