All business look to reduce energy usage in order to reduce operating and manufacturing cost. Governments around the world are looking to ensure that businesses take energy efficiency seriously, this is demonstrated with Energy Efficiency Directive (2012/27/EU) and the ESOS (Energy saving opportunity scheme) regulations.

At Seymour we design with energy and time saving in mind. We design machines to be energy efficient using the latest highly efficient technology, we also design so our machines are easy to use and maintain saving operational and maintenance time.

Our E-SHOP and E-Mill development propagates through all our business. Developments are shared from the New machine designs to the re-engineering and retrofit projects.

A Range of Seymour Designed and Manufactured Machines.

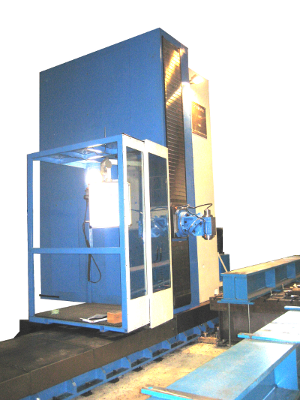

Taking existing machine components, Some Seymour designed new components and building refurbished and re-engineered machine types and travels that suit your requirements.

Machine Tools give many years of useful service. There eventually comes a time when they are not working efficiently any more or not working at all. With Seymour Retrofit and Re-Engineering these machines can be brought back into service as highly efficient and valued production machines once again.

The Gantry Mill Project was a complete re-design of the milling head and a conversion from NC Drilling to CNC drilling and milling.

Kolomna 1563 CNC Re-Engineering and Retrofit

The Kolomna 1563 Project included re-engineering and conversion to CNC.

Butler Elgamill Refurb, Re-Engineer and retrofit

The Elgamill T-Type Heidenhain Projects included re-engineering, refurbishment and retrofit.

Butler Elgamill Refurb, Re-Engineer and retrofit

The Elgamill T-Type Siemens Project included re-engineering, refurbishment and retrofit.

|

|

Email:- info@seymour-eng.com |

|

Siddal Hall Works, Phoebe Lane, Halifax, ENGLAND, HX3 9AS |  |

| TEL:- +44 (0) 1422 362 135 | FAX:- +44 (0) 1422 322 511 |